By admin | July 5, 2025

Relocating heavy machinery is a high-stakes task that demands experience, planning, and precision. Whether your business is upgrading facilities, expanding to a new site, or undergoing plant relocation, the way you handle heavy equipment can affect safety, compliance, and operational continuity.

Coleman Moving has supported San Diego businesses since 1979 with expert machinery transportation services. Below, we share actionable tips for moving heavy machinery, so your next move stays safe, efficient, and on schedule.

Understanding the Unique Challenges of Moving Heavy Machinery in California

California’s business landscape presents several obstacles when moving heavy machinery:

- Strict regulations on transportation permits and industrial relocation

- Dense urban environments requiring route planning and timing considerations

- Diverse terrain from coastlines to mountains, affecting access and trailer types

Moving equipment here often means managing oversized loads and securing specialized vehicles. Planning ahead is essential. Traffic patterns, construction zones, and local laws all affect timing, safety, and cost. Businesses also face tight deadlines when disassembling and reassembling equipment, often with minimal margin for error.

That’s why partnering with an experienced rigging company like Coleman Moving makes a measurable difference. We help you plan strategically, obtain necessary permits, and coordinate the logistics of every stage.

Equipment and Tools That Make Machinery Moves Safer

Using the right equipment helps protect your machinery, team, and timeline. Here are a few must-haves:

Toe jacks: Used to lift heavy loads with control and precision. These help position machines onto dollies or skates without putting personnel at risk.

Hydraulic lifting systems: Provide controlled, stable lifting for delicate or high-value machines. They reduce strain on mechanical components and allow for fine adjustments during positioning.

Heavy-duty dollies: Designed to evenly distribute weight and allow smooth movement over surfaces, including warehouse floors or uneven terrain.

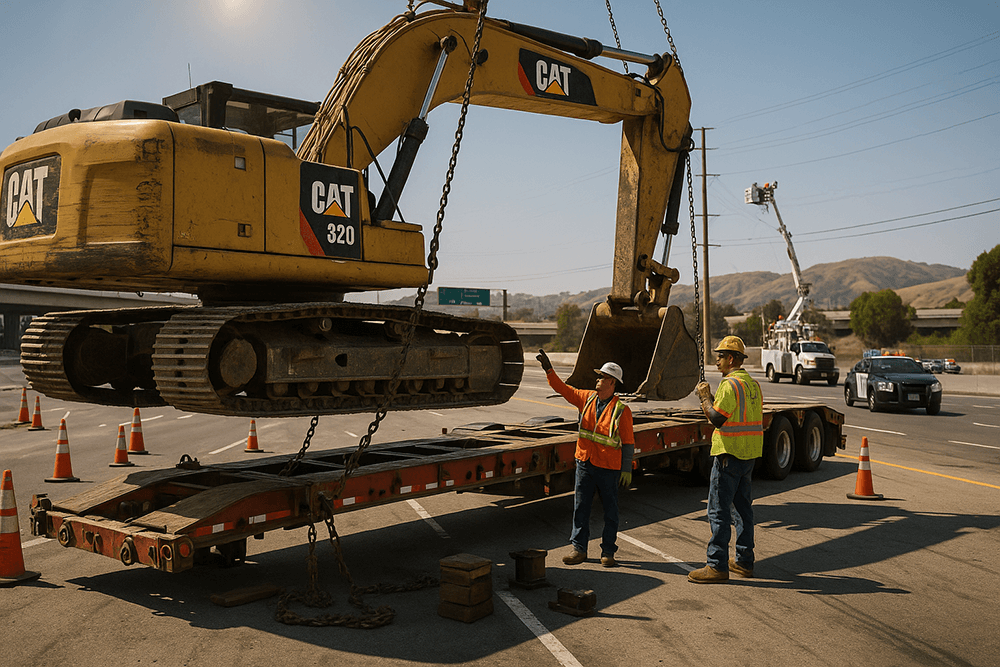

Rigging tools: Slings, chains, hoists, and spreader bars offer added security during lifting, loading, and unloading. Rigging is essential for complex equipment with uneven weight distribution.

Skates and rollers: These tools make short-distance movement easier, especially in tight spaces where forklifts or cranes cannot operate effectively.

Load binders and straps: Ensure that equipment stays secure during transportation, reducing the risk of shifting or tipping on the trailer.

Each tool serves a specific function and must be operated by trained professionals. Relying on experienced movers ensures your equipment is handled with care using the correct method for every stage. Proper equipment not only protects your assets but also helps maintain compliance with California’s strict safety standards for industrial moves.

Planning Tips for Moving Heavy Machinery Without Delays

Successful machinery relocation starts with detailed planning. Consider the following steps to stay organized and avoid disruptions:

Assess both locations: Identify clearance issues, floor load capacity, and accessibility. Check for utility lines, entry points, and potential obstructions at the new site.

Involve internal teams early: Everyone should understand roles, schedules, and any shutdowns that might affect productivity.

Schedule disassembly and reinstallation carefully: Build in buffer time for testing and adjustments. Equipment often requires calibration after reassembly to resume normal function.

Secure trailers and transport routes in advance: Oversized loads require specialized trailers, traffic escorts, and state permits.

Communicate with suppliers and contractors: Make sure everyone involved, from electricians, riggers, crane operators, is aligned on timing and responsibilities.

Partner with professionals: Working with machinery moving experts reduces stress and gives you access to best practices from past jobs.

A clear relocation plan helps prevent overlooked details that can cause costly delays. Coleman Moving supports businesses with step-by-step coordination to keep your project running smoothly.

Prioritizing Safety and Legal Compliance in Machinery Relocation

When moving heavy machinery, safety and compliance are non-negotiable. Accidents or missed permits can create costly delays or even legal setbacks. Here’s how to manage both:

Conduct site-specific risk assessments before disassembly begins. Identify potential hazards and create a step-by-step safety plan.

Provide safety briefings and protective gear for all team members involved. Clear communication helps reduce misunderstandings and workplace injuries.

Ensure machinery is properly secured to prevent shifting during transport. Use tested load restraints and conduct final checks before departure.

Double-check Department of Transportation and local requirements, especially when dealing with oversized equipment or highway travel. Failing to meet permit standards can lead to fines or forced stoppages.

Keep up with compliance checks throughout the move, not just before departure. Regular inspections help maintain accountability and identify gaps before they become issues.

Document procedures and incidents to stay prepared for audits or insurance claims.

A trusted rigging company like Coleman Moving can help enforce these standards. We handle the paperwork, ensure all equipment is secured using approved techniques, and maintain a safe jobsite from start to finish. Safety and compliance are not just regulatory requirements, they’re vital to protecting people, property, and long-term business operations.

Why Professional Movers Are Essential for San Diego Plant Relocations

Relocating a plant in Southern California is a specialized job. You may be moving a single piece of equipment or an entire production line. Either way, your business needs a moving partner that offers:

- Detailed project coordination

- Custom rigging solutions

- Experience with varied terrain and facility types

- Access to the right equipment and transportation

At Coleman Moving, we tailor every job to fit the client’s facility layout, machine types, and deadlines. We minimize downtime by managing every phase, from teardown to transit to reassembly, while protecting your investment throughout.

Our team uses modern lifting systems, route optimization, and strong communication to move your equipment efficiently, even in the most demanding conditions.

Partner With Coleman Moving for Expert Heavy Equipment Relocation

Moving heavy machinery is a job that requires more than manpower. It takes skill, specialized tools, and strategic planning to protect your equipment and avoid disruptions to your business.

Coleman Moving has served the San Diego region for over 40 years, handling complex machinery moves with care and precision. Our licensed professionals are equipped to guide you through every stage, offering reliable support tailored to your schedule and compliance needs.

Contact us today to discuss your project or request a quote for heavy equipment relocation services in California.